Welcome To Hawkrown Professional

Are You Visiting As A Business Buyer (wholesaler/retailer) Or A Homeowner?

Business Buyer

Continue Here >Homeowner

Shop Retail Store >

Home / Blog Center / Chargers / Why You Should Consider Thicker Cutting Blades for Tile Work

24/07/2025 | Hawkrown

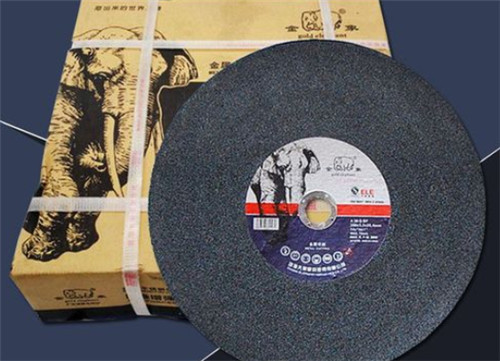

When utilizing tile cutting edges, there are numerous subtle elements to consider, and uncommon consideration is required to dodge affecting typical development. Is there a thicker tile cutting edge available?

Yes, there are thicker tile cutting blades.

There is no bound together standard for the thickness of tile cutting edges; distinctive cutting edges have changing thicknesses. For illustration, a 150 edge ordinarily has a thickness of around 1.0 to 1.6 millimeters. A 350 edge more often than not has a thickness of around 2.5 millimeters, whereas a 4000 edge can reach a thickness of roughly 3.2 millimeters.

In common, more slender cutting edges are favored since they spare generation materials, diminish bundling and transportation costs, and subsequently lower the last cost. Also, more slender cutting edges make less cutting resistance, driving to lower operational control utilization for the cutting machine.

What ought to you pay consideration to when utilizing a tile cutting edge for cutting tiles:

1. Some time recently introducing the cutting wheel, carefully assess it. If there are any flotsam and jetsam or harms, desist utilize immediately.

2. The revolution course checked on the cutting wheel must adjust with the machine's turn heading. If not, cutting will be wasteful, and the execution of the wheel will not be completely utilized.

3. Do not utilize cutting wheels that do not meet the details. If any variations from the norm are recognized amid the cutting handle, halt the machine quickly to distinguish the cause. If the cutting is gloomy, the wheel ought to be dressed to guarantee sharpness. Proceeding to utilize a gloomy wheel may lead to overheating and over-burden, possibly harming the wheel.

4. Amid the turn of the wheel, it is entirely taboo to touch the cutting wheel with hands or any portion of the body. The cutting wheel ought to not be utilized for cutting or operations other than cutting to dodge uneven stretch that can lead to abnormalities.

In outline:with respect to the accessibility of thicker tile cutting edges, this is the data given. As famous, there is no bound together standard for the thickness of tile cutting edges; they can shift essentially. For occurrence, the thickness of a 150 edge ranges from 1.0 to 1.6 millimeters, a 350 edge is around 2.5 millimeters, and a 4000 edge is around 3.2 millimeters.

Are You Visiting As A Business Buyer (wholesaler/retailer) Or A Homeowner?

Business Buyer

Continue Here >Homeowner

Shop Retail Store >